SERVICES

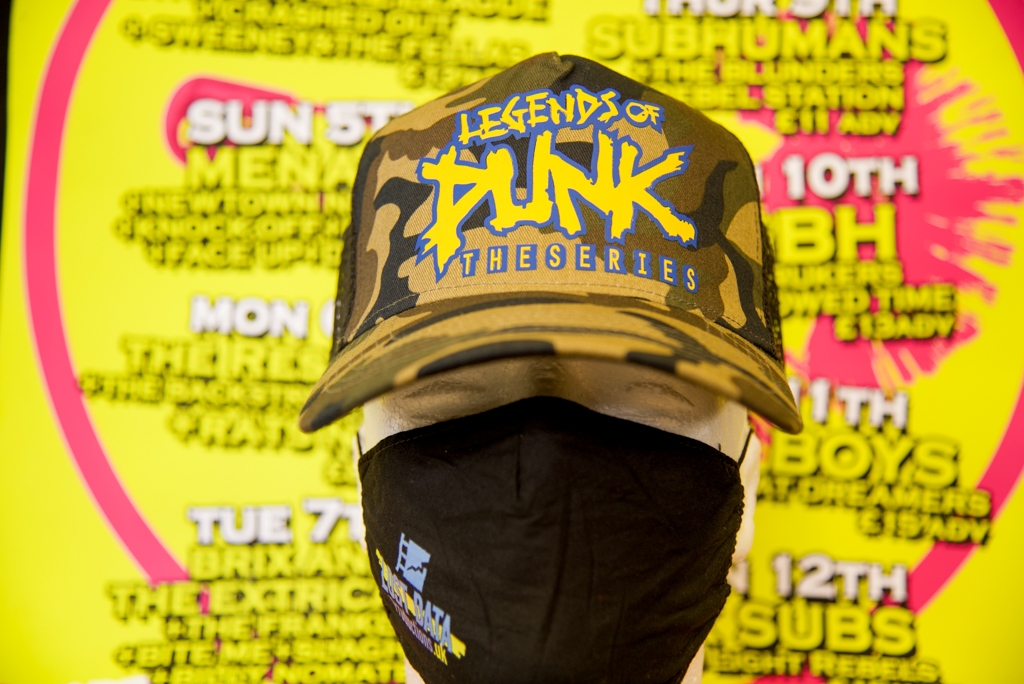

We provide a diverse range of printing services, which encompass headwear and garment printing, as well as sublimation printing for promotional gadgets and gifts. Our sublimation printing capabilities extend to items such as mugs, bottles, pads, bags, and various other popular merchandise products.

From the initial design phase to the final printing production, we offer comprehensive assistance throughout the entire process. We take pride in offering a wide selection of environmentally friendly and ethically produced clothing and merchandise options, ensuring that you can make choices that are not only best for you but also for the planet. Rest assured, our small and welcoming print shop operates without the use of harmful chemicals.

To accommodate your specific requirements, we employ five different printing techniques. This flexibility allows us to cater to a wide range of promotional products you may have in mind. Additionally, our advanced equipment and techniques enable us to handle projects of any scale, from small batches to large-scale endeavors. With us, there are no minimum order restrictions, ensuring that we can cater to your needs effectively.

Printed from raster (,jpg) image

Printed from raster (,jpg) image Printed from vector image

Printed from vector image

DTF (Direct to Film) brings together the superior quality of traditional screen print techniques with the adaptability and ease of digital printing. We conducted extensive testing on DTF transfers, subjecting them to over 50 washes, and the results were outstanding. These transfers are designed to maintain their visual appeal over time – they are truly built to last!

One of the notable advantages of DTF is the use of water-based inks, which eliminate the need for harsh or toxic chemicals. Additionally, the transfers are applied onto recyclable transfer paper, aligning with our commitment to sustainability.

The benefits of DTF are numerous. Firstly, it offers unlimited colour options, allowing for vibrant and eye-catching designs. Furthermore, DTF transfers possess excellent stretch and rebound properties, ensuring they won’t crack or deteriorate with movement. The soft finish of the transfers makes them seamlessly blend with the garment, providing a comfortable wearing experience. Moreover, these transfers can withstand over 60 washes, surpassing the new industry standard. Lastly, DTF is particularly suitable for capturing fine details with precision, making it an ideal choice for intricate designs.

In summary, DTF brings together the best of both worlds, combining the reliability of traditional silkscreen techniques with the versatility of digital printing. With its exceptional durability, eco-friendly inks, and outstanding performance, DTF transfers are an excellent choice for creating visually stunning and long-lasting designs.

Printed from raster (.jpg) image

Printed from raster (.jpg) image Printed from raster (.jpg) image

Printed from raster (.jpg) image

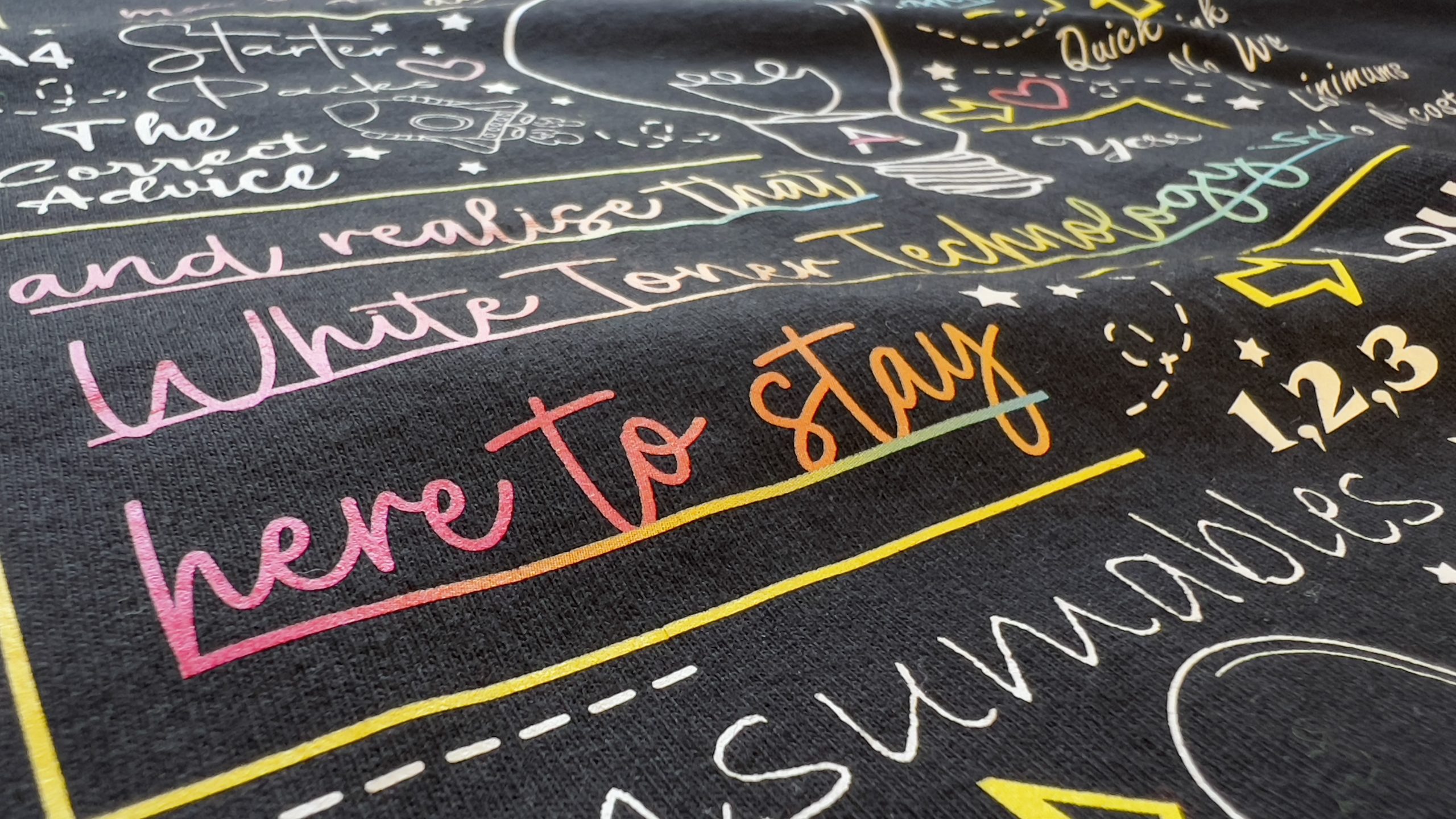

White toner printers have transformed the customization industry since their introduction a few years ago. Although they are primarily used for T-shirt transfers, their popularity is growing in producing promotional items like can coolers, coasters, mugs, ornaments, awards, and more.

These printers are widely regarded as an excellent alternative to direct-to-garment, sublimation, and even screen printing due to their versatility. They offer the flexibility to create custom apparel, promotional products, stickers, and other items, catering to diverse printing needs.

The significance of white toner lies in its ability to address a persistent challenge in transfer printing. Traditional CMYK transfers (using plain color laser or inkjet) often yield lackluster colors when applied to dark T-shirts or hard goods. It’s akin to applying a new coat of paint to a wall already painted black, red, or brown. Without a primer, the colors appear muted. White toner serves as that primer for T-shirt printing, enabling vibrant and precise color reproduction on dark garments.

On the other hand, sublimation transfers can only be applied to light-colored (mostly white) synthetic materials like polyester, as they don’t utilize white toner. However, with the emergence of various white toner printer options in the market, the selection process becomes critical.

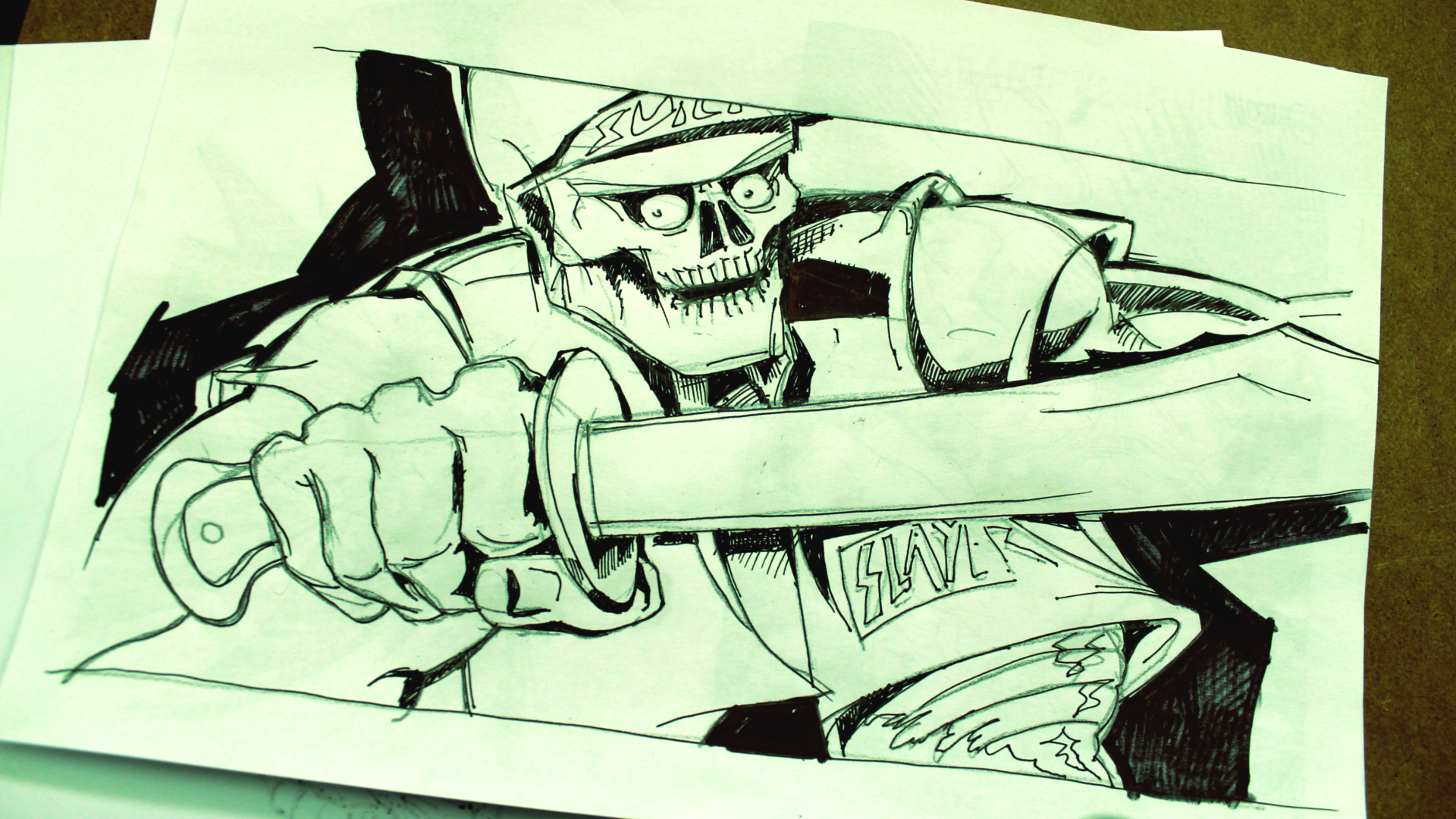

When it comes to creating bold prints with solid colour fills, Screen Printing Heat Transfers are the ideal choice. They work particularly well for items like band name prints, hoodies, and logos with 1-5 colours that require specific Pantone® PMS colours. You can select from our range of 30 industry colours, or if you have a specific colour mix in mind, simply let us know in the comments when placing your order.

There are several benefits to using Screen Printing Heat Transfers. Firstly, they possess excellent stretch and rebound properties, ensuring that they won’t crack or lose their integrity with movement. The soft finish of the transfers seamlessly blends them with the garment, creating a cohesive and comfortable feel. Additionally, these transfers are built to last, withstanding over 60 washes while maintaining their appearance. Moreover, they are highly effective for capturing fine details, making them a great choice for intricate designs.

Custom Heat Transfers offer an effective, high-quality, and efficient method to incorporate your designs onto garments. They provide a reliable way to achieve visually appealing results without compromising on durability.

If you have a design that primarily consists of lettering, our Heat Transfer Vinyl service is perfect for you. With our state-of-the-art cutting plotter, we can swiftly cut out the design with precision. Our knowledgeable team will assist you in selecting the ideal vinyl from our extensive range of materials and colours.

For Heat Transfer Vinyl, we trust renowned brands such as Siser from Italy and Stalhs from the United States. These brands prioritize eco-friendly and vegan-friendly products, aligning with our commitment to sustainability. The vinyl we use is compatible with various fabric types, allowing for versatility in your projects.

We offer the option to attach various types of patches to baseball caps, beanies, or any other garment you desire. Whether it’s patches featuring the band name, tour name, or venue name, we can affix them all onto the same cap. When it comes to ironing on patches, it’s important to ensure the patch has adhesive on the underside. If you already have patches without glue, don’t worry! We can add the necessary adhesive for you. The best part is, there’s no minimum order quantity required. So, whether you need just a few or a larger quantity, we’ve got you covered!

Sublimation printing is a method used to transfer your design onto materials or fabrics using ink and heat. From a scientific perspective, it involves the direct transition of a substance from a solid state to a gas state, bypassing the liquid state. This transformation occurs at specific temperatures and pressures.

The process begins by printing your design onto a specialized paper, which is then transferred onto another material. For fabrics, this material typically needs to be polyester or a polyester blend, while items like mugs and coasters require a special polymer coating. The ink is heated, causing it to permanently adhere to the surface of the product.

There are several benefits to sublimation printing. It is a speedy and efficient process, making it ideal for smaller batch orders. It yields excellent results even with intricate and complex designs, providing you with greater creative freedom. Sublimation printing also allows you to choose a design that can cover a significant portion of your product. Moreover, designs produced through sublimation printing do not crack, peel, or fade over time.

You may wonder what types of items can be sublimated onto. Sublimation is suitable for garments made of polyester or polyester blends, as well as various blanks that have a special polymer coating, such as our mugs and coasters.

However, it’s important to note that sublimation on dark-colored garments is not possible due to the lack of white sublimation ink. The process relies on the white background of the fabric or material to showcase the vibrant colors and details of the design.

In summary, sublimation printing offers a versatile and durable solution for transferring designs onto a range of items, including garments and promotional gadgets. Its efficient process, ability to handle intricate designs, and long-lasting results make it a popular choice for personalized and visually striking products.